- Eddy Current Testing (ECT)

- Eddy Current Array (ECA)

- Internal Rotary Inspection System (IRIS)

- Near Field Testing (NFT)

- Near Field Array (NFA)

- Remote Field Testing ( RFT )

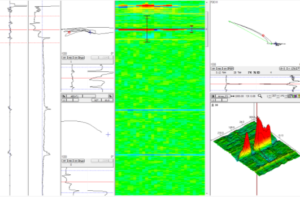

Eddy Current Testing (ECT)

ECA tube testing probes, efficiently detect circumferential cracks at tube support plates and tube sheets—something conventional bobbin probes notoriously fail at. These probes can also detect and size typical defects in any orientation such as wear, corrosion, and micro pitting, as well as detect Stress Corrosion Cracking (SCC). Compared to standard ECT bobbin probes, the ECA probes can discriminate between the various complex geometries inside heat exchanger and condenser tubing to allow accurately detecting, sizing, and characterizing small-volume longitudinal and circumferential cracks.

APPLICATIONS

- Convenient analysis with strip chart for bobbin and 2D/3D C-scans for array imaging.

- Includes a differential bobbin set and a circumferentially-sensitive pancake array.

- Detection of circumferentially-oriented cracks.

- Better detection capability in the transition zone.

Eddy Current Array (ECA)

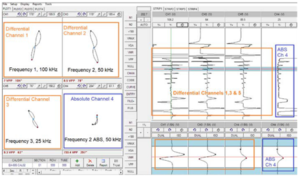

This method employs a bobbin-type probes (see bobbin type) that contains two AC coils wound in opposing directions. Each coils induces a localized electrical field around the tube. The impedance of the coil/coils changes as the electromagnetic field interacts with the material being tested. The coil is placed in the tube and the instrument is calibrated on a reference standard having known, machined discontinuities. The probe is pulled through the tube and variations in coil impedance are recorded. These changes, which are related to the types and sizes of discontinuities, can be displayed on a screen for final analysis and evaluation. Phase analysis and signal amplitude are utilized to assess the depth, origin and size of flaws.

APPLICATIONS

- Suitable for nonferrous tubing such as SS304/316, brass, titanium, copper, copper-nickel etc.

- Heat Exchangers

- Chillers

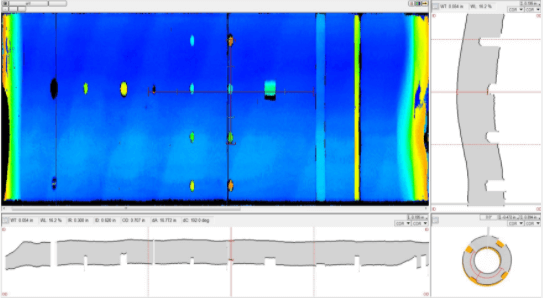

Internal Rotary Inspection System (IRIS)

Heat exchanger tubes are often scanned using one inspection technique, and then re-inspected with another to confirm the remaining wall thickness. IRIS testing is often used as a secondary technique.

The IRIS probes operate in pulse-echo mode to measure wall thickness, material loss, and defect orientation within the range of 0.5 in. to 3 in. ID. IRIS turbines are propelled by water pressure to make them rotate and include a 45° angled mirror that deflects the ultrasonic beam towards the tube wall.

APPLICATIONS

- RIS testing in ferrous and non-ferrous heat exchangers can detect a variety of defects

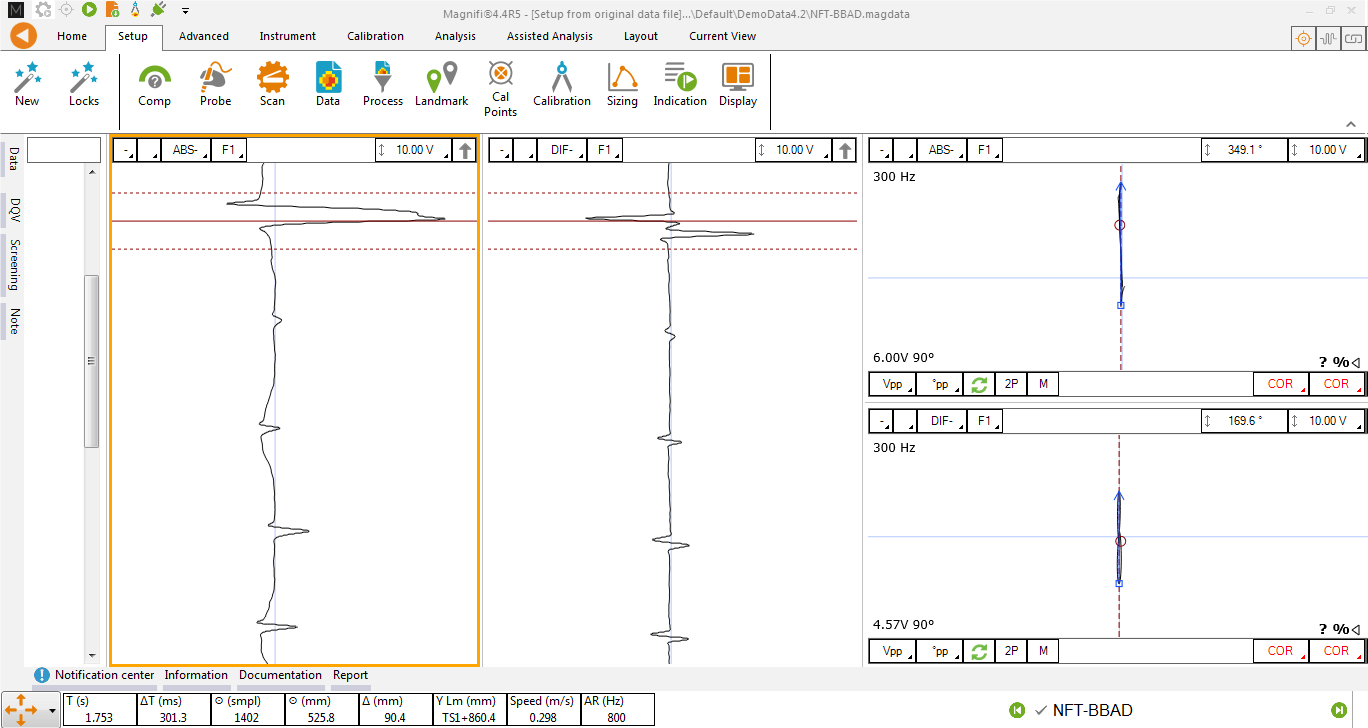

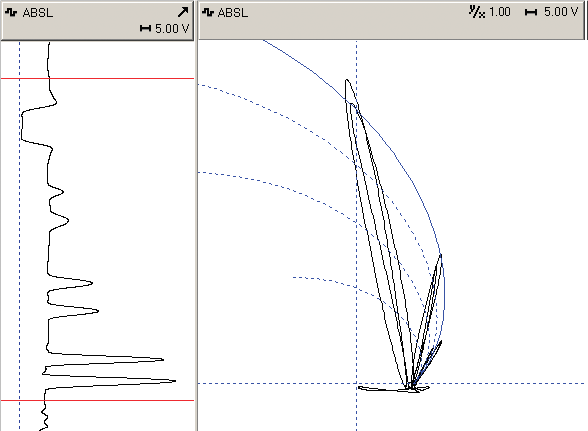

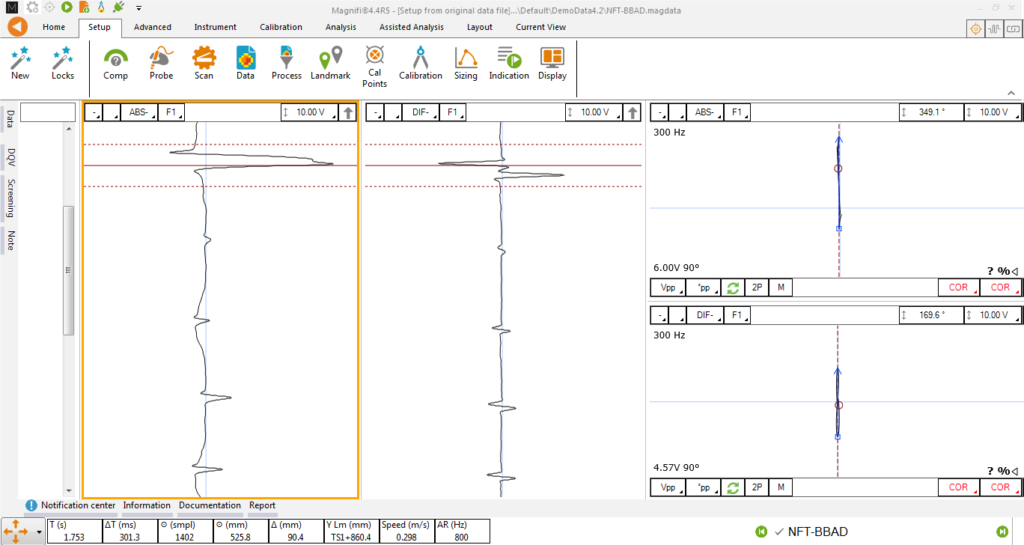

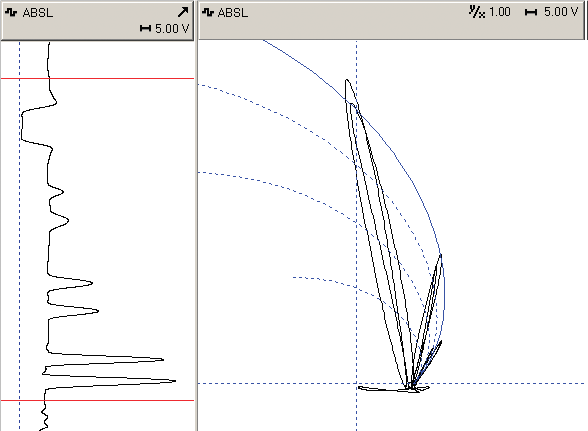

Near Field Testing

The near field testing (NFT) eddy current technology is a rapid and inexpensive inspection solution designed specifically for ID defect detection in carbon steel fin-fan tubes. NFT probes reduce cost and improve ease of use because they do not require expensive and cumbersome externally referenced coils.

Near field probes are an excellent alternative to magnetic flux leakage (MFL) probes. This new technology, which is based on a simple eddy current exciter/pickup design, produces signals that are very easy to analyze. Unlike MFL, these probes don not have a permanent magnet, making the probe pulling easier.

APPLICATIONS

- Ideal for carbon steel fin-fan tubes

- Heat Exchangers and boiler tubes

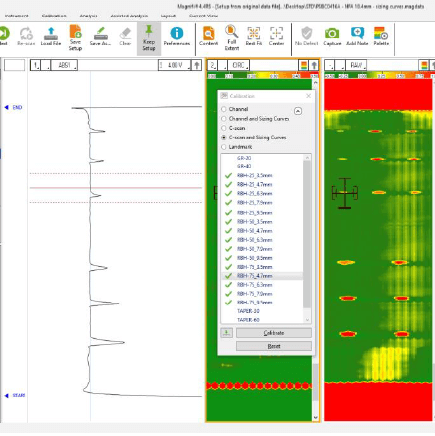

Near Field Array Testing

NFA probes can easily detect common defects found in fin-fan air cooler tubes or ferromagnetic heat exchangers. They include: Inner Diameter (ID) pitting, internal cracking at the tube sheets, internal erosion, and wall loss.

APPLICATIONS

- Fin-Fan Air-Cooled Heat Exchangers

Remote Field Testing

Remote field testing is a through-wall transmission technique. The basic probe is made of one exciter coil and two pickup coils. Two magnetic fields are present: the direct field, in the vicinity of the exciter coil, is rapidly attenuated with distance while the indirect field propagates along the tube axis and is re-diffused back through the tube wall.

The zone where the indirect field is dominant is called the remote field. This zone is present at a distance greater than 2 tube diameters. All remote field probes have their pickup coils set at 2.5 to 3 times the tube OD to ensure that only the indirect field is picked up.

APPLICATIONS

- Suitable for ferrous tubing such as Carbon steel

- Heat Exchangers and boiler tubes